NEXT-GENERATION ULTRA-HIGH-SPEED MICROWAVE

Photonic integrATed circuiTs using advancEd hybRid iNtegration

INP Platform

Main Advantages

Direct bandgap semiconductor

- Light emission at 1.55 µm

- Light detection at 1.55 µm

Higher electron velocity compared to silicon or gallium arsenide

- Bandwidth of waveguide-integrated photodiodes already achieved > 100 GHz

- Modulator up to 70 GHz

Main weaknesses

- Propagation losses few dB/cm

- PIC density: radius of curvature waveguide > 500µm

Ready for hybrid integration

- Flip-chip with grating couplers on the LNOI chip

- Edge-coupled (multiple die approach )

- Evanescent coupling based on μTP

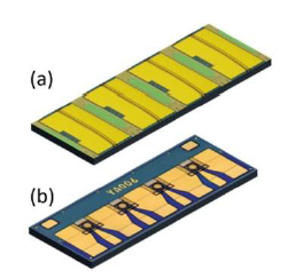

Example of flip-chip-compatible InP gain chips (a) and PD (b) developed by HHI

Beyond the state of art: To realise high-performance InP-on-LNOI devices, e.g. fast narrow linewidth tunable lasers, current InP gain chips and SOAs have to be optimised with regard to low power consumption (low heat dissipation) and efficient optical coupling to LNOI waveguides.

μTP requires optimisation to implement underlying sacrificial layers that allow for a full underetching of the respective InP gain chip and SOA structures.

In PATTERN, HHI’s proven ridge-waveguide-based components will be further developed and optimised for this purpose. New processing steps will be added to the existent InP processing technology. For the InP photodiodes, the design of flip‐chip-compatible surface-illuminated photodiodes needs to be optimised to allow for speeds > 100GHz, while maintaining a sufficiently high responsivity.